Wire Wrapped Stainless Steel Screen Pipe

Basic Info

| Model NO. | DN 27-1300mm |

| Type | Filter Elements |

| Hole Shape | Square |

| Structure | Single Network |

| Size | DN273X1.0X3m |

| End Connection | Threaded |

| Surface Treatment | Electrolytic Polishing , Pickling and Polishing |

| Apply for | Stainless Steel Water Well Screen Pipe |

| Transport Package | Wooden Box |

| Specification | Diameter: 1-30inch |

| Trademark | XL |

| Origin | Anping, Hengshui |

| HS Code | 84139100 |

| Production Capacity | 300m Per Day |

Packaging & Delivery

Package size per unit product 3040.00cm * 1400.00cm * 670.00cm Gross weight per unit product 800.000kgProduct Description

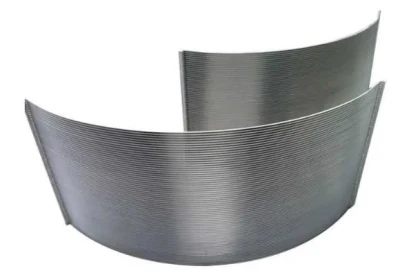

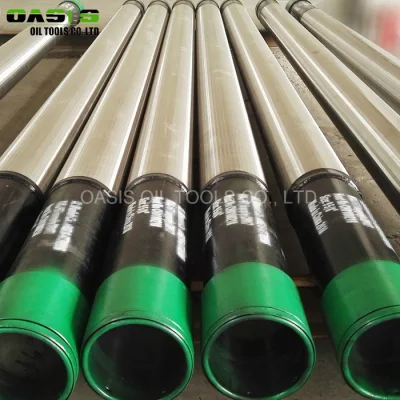

Wire-wrapped stainless steel screen pipe

Product Quick Details1. Name: Wire-wrapped stainless steel johnson strainer, oil well filter pipe2. Material: SS3043. Feture: No magnetic, High Tensile strength, No Angle And No Burrs, Non-clogging 4. Wrapped Wire: 2.5x4mm, 3x4.6mm5. Support rod: 3.8mmXinlu Wire Mesh Products offer Water Well Screens for wide range of well completion and work over operations.These screens are known in variety of names like water well screens , wedge wire well screens, v wire screens, continuous slot well screens, wire wrapped screens etc.A wedge shaped wire is wrapped / spirally wound on internal array of support rods. Each and every intersection is welded automatically. This creates a continuous non clogging slot.Sizes : Right from 4" dia to 36" dia & aboveSlot : From 0.15 to 1.5mm & aboveLengths : 10 ft, 20 ft up to 40 ft in single piece constructionMaterial of Construction : Stainless Steel-300 Series, Duplex & Super Duplex Stainless SteelsFeatures of wedge wire screen pipe1. High Open AreaMore than 25% of open area allows water to seep through the dewatering screen at a reduce speed, while allowing for a lower flow resistance. The enhances the water removal rate, resulting in a more efficient water removal process.2. Non-clogging PerformanceContinuous slots widen inwardly from the screen surface to minimize the chance of sand clogging the slot opening,3. Excellent Pressure ResistanceThe wedge wire screen is welded in a single from with no weld seams on the surface. Precise welding technology gives the screen its strength, making it ideal from high pressure applications4. Great Sand BarrierPrecisely machined slots keep sand, silt and clay from entering the well, preventing abrasion.5. Easy InstallationCompared to bridge slot screens or cement pipes, the wedge wire well screen in lightweight and easy to lay on the ground. It is also safe and convenient.6. MaterialThe screen is available is galvanized, low-carbon steel, or stainless steel in grades 304 and 316, Premium materials do not retain sand and other impurities, ensuring a non-clogging performance.

Screen Size | Inside Diameter | Outside Diameter | OD of Female Threaded End | ||||

in | mm | In | mm | in | mm | In | mm |

2 | 51 | 2 | 51 | 25/8 | 67 | 23/4 | 70 |

3 | 76 | 3 | 76 | 35/8 | 92 | 33/4 | 95 |

4 | 102 | 4 | 102 | 45/8 | 117 | 43/4 | 121 |

5 | 127 | 5 | 127 | 55/8 | 143 | 53/4 | 146 |

6 | 152 | 6 | 152 | 65/8 | 168 | 7 | 178 |

8 | 203 | 8 | 203 | 85/8 | 219 | 91/4 | 235 |

10 | 254 | 10 | 254 | 103/4 | 273 | 113/8 | 289 |

12 | 305 | 12 | 305 | 123/4 | 324 | 133/8 | 340 |

14 | 356 | 131/8 | 333 | 14 | 356 | _ | _ |

16 | 406 | 15 | 381 | 16 | 406 | _ | _ |

20 | 508 | 18 3/4 | 476 | 20 | 508 | _ | _ |

PROFILE WIRE | ||||||||

| WIDTH(mm) | 1.50 | 1.50 | 2.30 | 2.30 | 1.80 | 3.00 | 3.70 | 3.30 |

| HEIGHT(mm) | 2.20 | 2.50 | 2.70 | 3.60 | 4.30 | 4.70 | 5.60 | 6.30 |

SUPPORT ROD | ROUND | |||||

| WIDTH(mm) | 2.30 | 2.30 | 3.00 | 3.70 | 3.30 | Ø2.5--Ø5mm |

| HEIGHT(mm) | 2.70 | 3.60 | 4.70 | 5.60 | 6.30 | ---- |

Why choose us ?

1. We are the professional manufacturer.2. We can give you the best quality products with competitive price.3. Professional sales team can give you feedback within 24 hours.4. We offer 12 months excellent after-sale service.5. We offer customized service.6. Our service is available twenty four seven, that is twenty four hours a day and seven days a week.