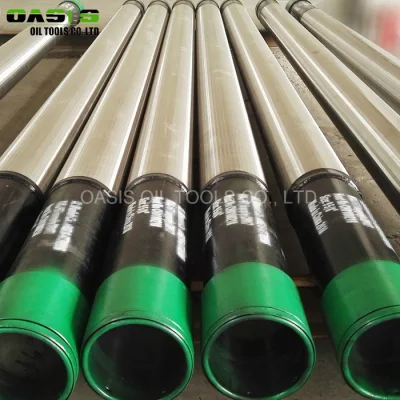

Double Layer Pipe Perforated Based Screen and Johnson Well Screen

Pipe base screen Introduction of pipe based screens Pipe based screens consist of base pipe,all-welded wedge wire screen;

Basic Info

| Model NO. | OA-W-340 |

| Temperature Classification | High Temperature Piping |

| MPa Classfication | Ultra High Pressure Piping |

| Material | Stainless Steel Pipe |

| Standard | ASTM, GB, API |

| Diameter | 273mm |

| Medium | Liquid |

| Cross-Section Shape | Round |

| Connection Type | Welding |

| Slot Size | 0.02mm-15mm |

| Length | 1-6m |

| Application | Water/Oil Well Filter |

| Width | 33-1500mm |

| Thickness | 5-10mm |

| out Diameter | 15mm - 275mm, Customized |

| End Connection | Welded Ring, Threaded Coupling, Flange |

| Technique | Polishing & Wire Wrapped & Welding |

| Feature | Corrosion Resistance |

| Transport Package | Wrapped by Plastic Bag+Wooden Box |

| Specification | OD340MM |

| Trademark | OASIS |

| Origin | Henan, China |

| HS Code | 743125000 |

| Production Capacity | 8500meters/Month |

Product Description

Pipe base screenIntroduction of pipe based screens

Pipe based screens consist of base pipe,all-welded wedge wire screen and supporting rod.The base pipe is perforated or slotted API casing pipe,the base pipe can be stainless steel or carbon steel API 5CT casing.The all-welded wedge wire screens are welded together with base pipe by supporting rod.

Features of pipe based screens:

1.Higher filtering accuracy: all-welded wedge wire screens as screen jacket with vee opening design makes the filtering accuracy higher,which can control sand better.

2.Excellent strength and resistance to deformation: The base pipe inside,the outside can be protected with the protection jacket added according to requirements,the integrated strength of the perforated base pipe only decreases 2~3% compared with the standard casing/oil tubing,so the pipe based well screens have enough integrated strength to resist to the pressure caused by strata.Even if some part of the well screens deformed,the slot of this part will not be widened,which makes higher sand control reliability.

3.More choices: the material of screen jacket can be stainless steel or carbon steel,the material can be chosen as per customers' requirement.

4.The smaller slot will increase the oil and gas production.

5.The excellent technique makes the mass production with high efficiency and low cost available.

6.The specifications can be customized according to customers' requirements.

Grade :SUS 304 SUS304L, SUS316, SUS316L, or carbon steel

Slot Size: 0.02mm~15mm

Standard: DIN AISI ASTM

Technique: Polishing&Wire wrapped&Welding

End connection: Welded ring, Threaded coupling, Flange

Feature:Corrosion Resistance

| Pipe Based Screen | ||||||||||

| Base Pipe | Screen Jacket | |||||||||

| Nominal Diameter (in) | Outside Diameter (mm) | Weight (lb/ft) Wall Thickness (mm) | Hole Density | Hole Area (In2/ft) | OD of Screen Jacket (in) | OD of Screen Jacket (in) | Open Area (In2/ft) Slot (in) | |||

| 0.008" | 0.012" | 0.015" | 0.020" | |||||||

| 2-3/8 | 60 | 4.6(4.83) | 3/8 | 96 | 10.60 | 2.86 | 12.68 | 17.96 | 21.56 | 26.95 |

| 2-7/8 | 73 | 6.4(5.51) | 3/8 | 108 | 11.93 | 3.38 | 14.99 | 21.23 | 25.48 | 31.85 |

| 3-1/2 | 88.9 | 9.2(6.45) | 1/2 | 108 | 21.21 | 4.06 | 18.00 | 25.50 | 30.61 | 38.26 |

| 4 | 101.6 | 9.5(6.45) | 1/2 | 120 | 23.56 | 4.55 | 20.18 | 28.58 | 34.30 | 42.88 |

| 4-1/2 | 114.3 | 11.6(6.35) | 1/2 | 144 | 28.27 | 5.08 | 15.63 | 22.53 | 27.35 | 34.82 |

| 5 | 127 | 13(6.43) | 1/2 | 156 | 30.63 | 5.62 | 17.29 | 24.92 | 30.26 | 38.52 |

| 5-1/2 | 139.7 | 15.5(6.99) | 1/2 | 168 | 32.99 | 6.08 | 18.71 | 26.96 | 32.74 | 41.67 |

| 6-5/8 | 168.3 | 24(8.94) | 1/2 | 180 | 35.34 | 7.12 | 21.91 | 31.57 | 38.34 | 48.80 |

| 7 | 177.8 | 23(8.05) | 5/8 | 136 | 42.16 | 7.58 | 23.32 | 33.61 | 40.82 | 51.95 |

| 7-5/8 | 194 | 26.4(8.33) | 5/8 | 148 | 45.88 | 8.20 | 25.23 | 36.36 | 44.16 | 56.20 |

| 8-5/8 | 219 | 32(8.94) | 5/8 | 168 | 51.08 | 9.24 | 28.43 | 40.98 | 49.76 | 63.33 |

| 9-5/8 | 244.5 | 36(8.94) | 5/8 | 188 | 58.28 | 10.18 | 31.32 | 45.15 | 54.82 | 69.77 |

| 10-3/4 | 273 | 45.5(10.16) | 5/8 | 209 | 64.79 | 11.36 | 34.95 | 50.38 | 61.18 | 77.86 |

| 13-3/8 | 339.7 | 54.5(9.65) | 5/8 | 260 | 80.60 | 14.04 | 37.80 | 54.93 | 66.89 | 85.17 |

Quality Test:

1.All Dimensions of Best-Selling Stainless Steel Pipe Based Well Screen for Water Well will be checked by our quality inspector, and they also can be inspected by Third Party Inspections or representative appointed by buyer.

2.Wall thickness of casing is inspected by Ultrasonic inspection method, and they also be made the Ultrasonic flaw detection.

3.Do Destructive Collapse Test and collapse Strength Test before shipment.

4.If required, the casing will be made pickling and passivation treatment.

5.The whole manufacturing process can be monitored by Third Party Inspection Company and representative appointed by buyer.

6.The casing will be arranged the Pre-shipment Inspection if required.

Package:

1)Plastic threaded caps cover the both side of the pipes;

2)Wood support pipes;

3)Wire reinforce inside of the container;

4)Under the same shipping fees, we choose the quick shipping line to save time for the clients.

Company information:

Oasis Oil Tools Co.,LTD, located in the industrial park of high-tech enterprises in Fengquan District, Xinxiang City, covers more than 20000 square meters with more than 150 staff, among them 6 persons are senior engineer. OASIS is a famous manufacturer which integrates the research and development, design, manufacture and sell water well screens/ Johnson screens, oil well screens and sand control well screens, bridge slotted well screens, pipe based well screens, perforated pipe (base pipe), gravel pre-packed well screens, wedge wire screens, passive water intake screens etc. water, oil and gas well filtering products as well steel tubes and pipes and industrial parts.

Oasis has the right to export well screens independently. Our water well screens have been exported to Russia, Sudan, Tunisia, Morocco, Saudi Arabia, Slovenia, Indonesia, Philippines, Vietnam, Canada, Bolivia, Ecuador, Columbia etc. Countries, and have received good feedback from customer at domestic and abroad.

Contact:

Any enquiry about our products, contact us for more details. We are always ready to serve you at any time. Highly appreciate your question and visiting.

Add:Xuanhe West Road, Fengquan District, Xinxiang. Henan, China

Tel: 0086 373 2947626/Fax: 0086 373 3091997

Website: http://wedgewirescreen.en.made-in-china.com

You may also like

Send inquiry

Send now