Non Magnetic Wedge Wire Slot Sand Control Screens for Water Well

Basic Info

| Model NO. | XL--110 |

| Material | Metal |

| Application | Industry, Food and Beverage, Medicine, Textile, Metallurgy |

| Type | Resin Filter |

| Filter Connector | Flange, Threaded, Welded Rings |

| Filtration Grade | HEPA Filter |

| Activated Carbon Filter Type | Compact |

| Slot | 1mm |

| Length | 3000mm |

| Profile Wire | 2.5X4mm |

| Support Wire | 3.8mm / 48 |

| Transport Package | Wooden Box, Pallet |

| Specification | XL-SG-219 |

| Trademark | XL |

| Origin | Anping Xinlu Wire Mesh Factory, China |

| HS Code | 8413190000 |

| Production Capacity | 4444444444PCS/Year |

Packaging & Delivery

Package size per unit product 122.00cm * 93.00cm * 42.00cm Gross weight per unit product 90.000kgProduct Description

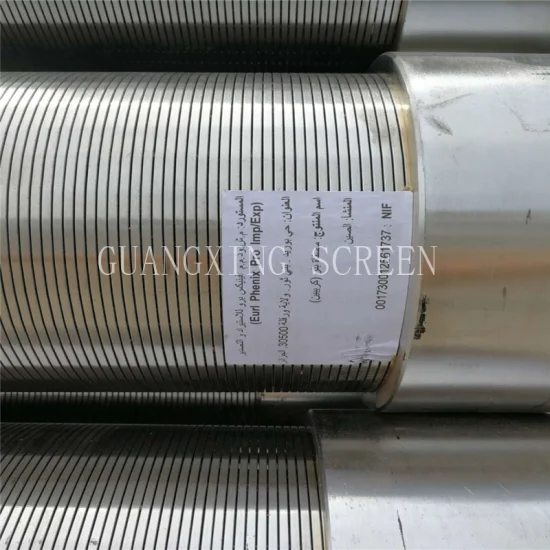

Non Magnetic Wedge Wire 0.25mm Slot Sand Control Screens Stainless Steel For Water Well

Stainless Steel 201 Wedge Wire Sand Control Filter Pipe For Water Well

Introduction of Wedge Wire Sand Control Filter Pipe:

Stainless steel wedge wire sand control filter pipe, also known as Johnson screen, water well screen, wound screen, wire wrapped screen,filter pipe, It is widely used in oil, gas, water well sand control industry, especially in the water well industry prominent position, widely used in water resources filter screen pipe. Stainless steel screen using full welding production process, the application of special trapezoidal wire winding in a circumferential arrangement of a group of supporting wire welding from.

Wedge Wire Sand Control Filter Pipe Normal Sizes:

Name: Johnson screen,Water wire screen,Water well screen, Wire warp screen,Wedge wire screen,Screen tube,Slotted tube,Wound screen,Continuous slot screen filter,Sand control screen, Wedge wire screen pipe, Rotary filter drum,Oil screen. | |||||||

| Material: Stainless steel 304,316L,Non-magnetic Stainless steel, Low carbon galvanized,904L,Duplex steel etc. | |||||||

| Diameter: From 29-1300mm (Normal diameter is in the below table) | |||||||

| Slot: From 0.1-100mm (Normal slot 0.5mm, 0.63mm, 0.75mm, 1.0mm, 1.5mm, Pls refer to below table) | |||||||

| Length: From 100-6000mm (Normal length is 2.9m and 5.8m, to fit container) | |||||||

| Wrap wire:2*3.5mm,2.2*3.5mm,2.2*4.5mm,3*4.6mm,3*5mm,3*6mm,3*6.5mm,3.2*6mm,etc. | |||||||

| Support rod:ø3.0-ø6.0mm round wire, Also can be Vee-shaped wire. | |||||||

| Ends:Welded rings/Plain beveled ends,Male/female threaded,Flange etc. | |||||||

Use:Water Well,Waste Water Treatment,Water supply systems,Coal & Mine,Food Processors & Beverage Screens, Environmental protection,Refining & Petrochemical,Architecture & Construction etc. | |||||||

Sizes (inch) | OD (mm) | Slot (mm) | Length (m) | Tenslie Strength | Collapse Strength | Wrap wire Vee-shaped wire(mm) | Support rod Round wire(mm) |

| 3-1/2 | 88.9 | 1.0 | 2.9 | >22 | 10.2 | 2.2x3.5 (Width x height) | ø3.8MM×22 |

| 4-1/2 | 114.3 | 1.0 | 2.9 | >28 | 11.5 | 2.2x3.5(Width x height) | ø3.8MM×22 |

| 6-5/8 | 168.3 | 0.75 | 5.8 | >40 | 12.8 | 2.2x3.5(Width x height) | ø3.8MM×32 |

| 6-5/8 | 168.3 | 1.0 | 5.8 | >33 | 12.8 | 2.2x3.5(Width x height) | ø3.8MM×32 |

| 6-5/8 | 168.3 | 0.63 | 5.8 | >83 | 45 | 3.2x6.0(Width x height) | ø6.0MM×32 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >34 | 21.9 | 2.3x3.5(Width x height) | ø3.8MM×48 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >50 | 38.2 | 3.0x5.0(Width x height) | ø4.0MM×48 |

| 8-5/8 | 219.1 | 1.0 | 5.8 | >60 | 46 | 3.2x6.0(Width x height) | ø5.0MM×48 |

| 10-3/4 | 273.1 | 0.75 | 5.8 | >50 | 32.9 | 2.2x3.5(Width x height) | ø4.0MM×55 |

| 10-3/4 | 273.1 | 1.0 | 5.8 | >60 | 39.5 | 3.0x4.6(Width x height) | ø4.8MM×55 |

| 10-3/4 | 273.1 | 1.0 | 5.8 | >100 | 48 | 3.2x6.0(Width x height) | ø5.0MM×55 |

| 12-3/4 | 323.9 | 1.0 | 5.8 | >120 | 37.2 | 3.0x5.0(Width x height) | ø4.0MM×56 |

| 14 | 355.6 | 1.0 | 2.9 | >80 | 37.8 | 3.0x5.0(Width x height) | ø4.0MM×59 |

| 16 | 426 | 1.0 | 2.9 | >80 | 37.5 | 3.0x5.0(Width x height) | ø4.0MM×54 |

Features of Wedge Wire Sand Control Filter Pipe:

1. The application of trapezoidal wire, so that a V-shaped opening is formed between the gaps of the screen tube.

2. The trapezoidal wire continuous winding forms a continuous high-density uniform gap on the supporting wire arranged in a circular manner.

3. The winding wire and all supporting wires are connected by electric welding, durable, long working life cycle.

4. According to the actual needs of the design of the support wire longitudinal arrangement and screen tube continuity gap form, so that the stainless steel screen high compressive performance.

5. The advantages of stainless steel screen improve the efficiency and life cycle of Wells.

Wedge Wire Sand Control Filter Pipe Use:

Water well

Water supply systems

Refining & petrochemical

Filter equipment

Drum Filter

Sand control

Any inquiry please don't hesitate to contact us ! Hope we can work together soon.---------------------------------------------------------------------------------------------------------------Our factory Xinlu Wire Mesh product co., Ltd located in Anping country, Hebei Province, China.Our mainly products are: stainless steel vee sharped wire / wrap wire, johnson screeen, water well screen / rod based wire wrapped screen, wedge wire screen, reverse wedge wire screen, stainess steel strainer pipe, v wire slot tube, perfect roundness well screen pipe, dewatering well screen, dewatering screen panel, wedge wire grating, v wire flat panel, screen nozzle, water and gas strainer nozzle, stainless steel filter nozzle, wedge wire support grids, sieve bend plate, v wire screens, ARC screen, filter bottom nozzle, stainless steel lateral screens, wedge wire filter candles, Rotary drum screens, strainer cylinder, sand control well screen, oil well screen, rod basedc ontinuous slot screens, header and hub laterals & hub radial laterals etc.