China Manufacturer Beer Candle Filter Element Johnson Screen Tube Slotted Screen Tube Automatic Backwash Wedge Wire Screen Strainer Tube Screen Cylinder

China manufacturer Beer Candle Filter Element COMPANY PROFILE Founded in 1997, after 20 years of development, we have be;

Basic Info

| Model NO. | GX38 |

| Material | Metal |

| Application | Industry |

| Type | Wound Filter |

| Filter Connector | Thread |

| Filtration Grade | Medium Filter |

| Activated Carbon Filter Type | Stainless Steel Johnson Type |

| Diameter | 38mm |

| Length | 1000mm |

| Transport Package | Wooden |

| Specification | OD38*1000mm |

| Trademark | GUANGXING |

| Origin | Hebei, Hengshui |

| HS Code | 8421999090 |

| Production Capacity | 100000 |

Product Description

China manufacturer Beer Candle Filter ElementCOMPANY PROFILE

Founded in 1997, after 20 years of development, we have become the largest exporter of wedge wire screen in China.

- Slottle screen -Beer Candle Filter Element- Wedge wire filter

- Water & Oil well screen

- Wedge Wire Intake Screen

- Ballast Water Filter Element

- Wedge Wire Rotary Screen

- False bottom screen

- Wedge Resin Trap Screen

- Sugar Mill Screen

- Sieve Bend Screen

- Lateral Assemblies

- Filter Nozzle

We have nine production lines, a professional technical team, an independent quality inspection system, and a perfect after-sales service team, which can provide customized processing services for global customers.Filter screen introduction

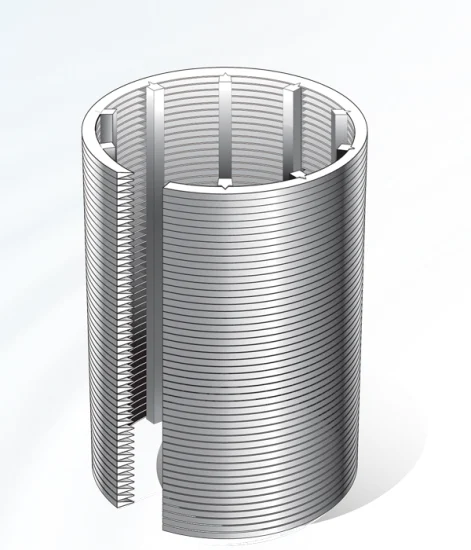

Brief introduction of Diatomite Candle Filters wedge wire screen elements

Precoat Filtration on Diatomite Candle Filters/keselguhr alluvial filters is the most widespread method of beer filtration today. And it is also suitable for all kind of precoat filtration, typical applications include filtration of beer, wine, beverages in general, syrups, gelatin, liquid food components. Basically any liquid solid separation where hygienic requirements exist.

Specification

Hengshui guangxing screens manufacture wedge wire screen fitler candles,Beer Candle Filter Element for these precoat filters .These filter candles with a diameter from 25 to 38 mm and a length from 1000 to 2000 mm have slot openings from 20 μm to 60 μm.Advantage

Diatomite precoating is stable. The candle filter has a unique self-supporting structure, which can withstand very large pressure and does not deform with the change of pressure. After diatomite precoating is formed on the surface, the coating is stable, and there is no coating crack and soil leakage.

High filtration precision. The slot of the candle filter is even. It can effectively intercept diatomite and form uniform precoating rapidly.

Not easy to block, easy to backwash. The outer narrow and inner wide gap structure enables the filter element to have "self-cleaning" function, and impurities will not be stuck, the surface of the candle filter is very smooth without any dead corner of residue. The backwashing process is more thorough and the cleaning effect is ideal.

The seepage velocity is small. Compared with other filter elements, the flow rate of liquid passing through the candle rod is smaller, the pressure drop is smaller, and the liquid is more stable.

Various materials. Different materials can be selected according to the specific use environment, which has reached the requirements to wear resistance, high-temperature resistance, and corrosion resistance. Commonly used materials are stainless steel 304316l, 904L, and Hastelloy, etc. customers can also specify the material.Product advantages of Wedge wire filter candle?

The Wedge wire filter candle has good roundness, small gap uniformity error, minimum gap control of 20 microns, and tolerance control of 5 microns. The product is not easy to be blocked, has a firm structure, high temperature resistance, corrosion resistance, good mechanical properties, long service life, safety and reliability, etc. It can be used for filtration of various media.

Precise V-wound wire with self-cleaning function, which is good for backwashing and not easy to block.

Smooth surfacewithout edges and corners, excellent roundness

Uniform gap, minimum gap control at 20 microns, error 0.005mm, can be customized according to customer's requirements

Diversified structure, various filtering directions, flexible customized production according to customer requirements, the filtering direction can be adjusted according to customer requirements, from inside to outside or from outside to inside.

The skeleton structure of self-supporting welding has high strength and large pressure bearing

Corrosion resistantand long service life

Material selection:stainless steel 304, 316L, 904L, titanium, Hastelloy

| NAME | WIDTH | HEIGHT | SECTION AREA | ANGLE |

| in / mm | in / mm | in2 / mm2 | ||

| 20 | 0.020 / 0.508 | 0.040 / 1.016 | 0.005 / 0.323 | 11 |

| 30 | 0.030 / 0.762 | 0.050 / 1.270 | 0.001 / 0.645 | 13 |

| 47 | 0.047 / 1.194 | 0.088 / 2.235 | 0.003 / 1.935 | 10 |

| 63 | 0.060 / 1.524 | 0.100 / 2.540 | 0.004 / 2.581 | 13 |

| 69 | 0.071 / 1.803 | 0.177 / 4.496 | 0.010 / 6.452 | 7 |

| 93 | 0.089 / 2.261 | 0.138 / 3.505 | 0.009 / 6.806 | 13 |

| 118 | 0.116 / 2.946 | 0.185 / 4.699 | 0.015 / 9.677 | 13 |

| 130 | 0.130 / 3.302 | 0.250 / 6.350 | 0.023 / 14.839 | 8 |

| 158 | 0.158 / 4.013 | 0.239 / 6.070 | 0.028 / 17.94 | 8 |

| 191 | 0.195 / 4.953 | 0.363 / 9.220 | 0.055 / 35.484 | 5 |

You may also like

Send inquiry

Send now